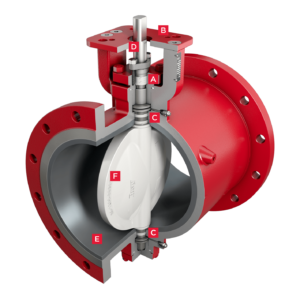

2 PC FLOATING BALL VALVE

₮0.00• size range: 1/2”-12”, DN15- DN300

• pressure rating: Class150- Class600, PN16-PN100

• cast steel body material: WCB, CF8, CF8M, CF3, CF3M

• forged steel body material: A105, LF2, F304, F316

• seat: PTFE, RPTFE, TMF1600 PEEK, NYLON, DEVLON, MO- LON

• Applicable temperature: -60°C to 260°C

• Operation: Handle, handwheel, turbine box, electric head, pneumatic head