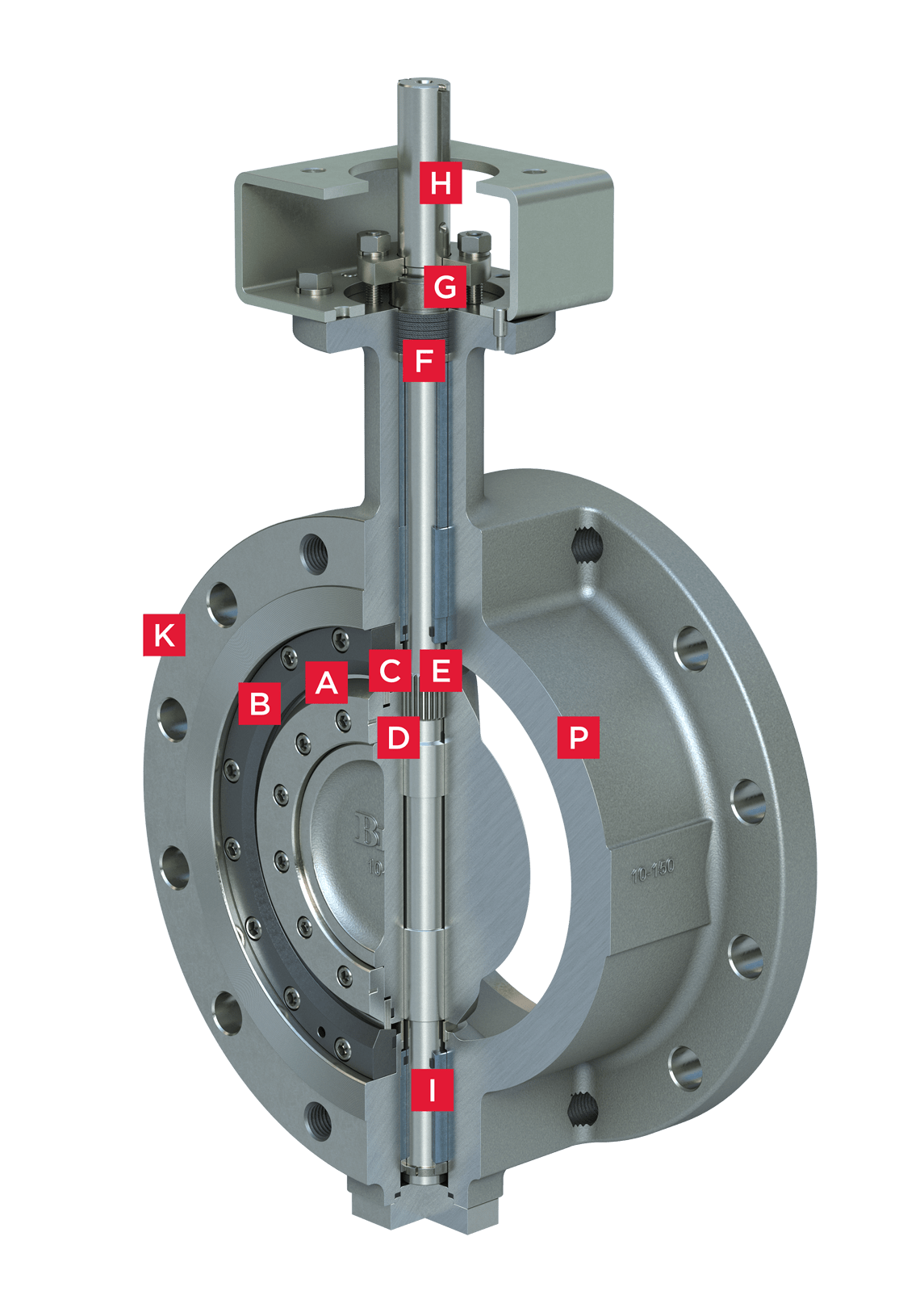

TRI LOK TRIPLE OFFSET BUTTERFLY VALVE

- Size Range:3” – 48” (80mm – 1200mm)

- Body Style:Wafer, Lug, Flanged and Gate

- Temperature Range:-320oF to 842°F (-196°C to 450°C)

- Pressure Ratings:ASME Class 150, 300 and 600

- Shutoff Rating:Zero Leakage

- Body Materials:Carbon Steel, Stain- less Steel & Other Materials Upon Request

- Disc Materials:Carbon Steel, Stain- less Steel & Other Materials Upon Request

- Stem Materials:410 SS, 17-4PH, & XM-19 (Nitronic 50)

- Seat Materials:316 SS Hardened, 316 SS

- Fugitive Emissions:ISO 15848-1, API 641, TA Luft

Features & Benefits

Bray proudly offers the Tri Lok triple offset butterfly valve, a premier isolation valve well-suited for operation in light vacuum to high-pressure applications and ideally suited for applications requiring absolute zero leakage. Compared to gate, globe or ball valves of the same size and pressure class, Tri Lok provides space and weight savings while minimizing installation and maintenance costs.

Tri Lok’s, non-rubbing, metal-to-metal seal delivers zero leakage with minimal torque and is certified fire-safe. The resiliency of the seal ring ensures uniform peripheral sealing with the seat, achieving full shutoff regardless of flow direction. Tri Lok offers a solid metal seal ring for high-temperature and severe service applications to ensure bi-directional shutoff throughout the full pressure/temperature range.

Bray Tri Lok is the only valve in its class with a splined disc/stem connection. The Tri Lok connection allows axial movement of the disc independent of the stem, keeping the seal ring and seat in position and unaffected by temperature fluctuations and pressure effects on the stem. This design prevents the typical misalignment problems of rigidly attached discs and stems to offer maximum strength. Close tolerance engagement between the disc and stem minimizes hysteresis.

Triple Offset Geometry

The Triple offset valve or triple eccentric valve features a stem that is offset on both the X (1) and Y (2) axis of the butterfly valves center-line. This produces a cam-like motion as the valve operates. The third offset (3) consists of an inclined conical profile machined into the valve sealing surface, allowing rotary engagement and disengagement of the seat and seal ring without interference. This triple offset eliminates all rubbing between the seat and seal ring during valve travel, reducing seat and seal wear and extending cycle life.

Once the seat and seal ring are fully engaged, torque is applied in order to create a bi-directional, zero leak, metal-to-metal seal. For this reason, triple offset valves are often defined as “torque-seated” rather than “position-seated” as in the case of resilient or high-performance products.

Reviews

There are no reviews yet.