PTFE BELT, TEFLON BELT

₮0.00material: glassfiber or Kevlar coated PTFE

• quality: premium grade

• color: brown, black, blue etc.

• surface: smooth/smooth

• temperature resist: -140°C – +260°C

material: glassfiber or Kevlar coated PTFE

• quality: premium grade

• color: brown, black, blue etc.

• surface: smooth/smooth

• temperature resist: -140°C – +260°C

• material: pure PTFE dispersion resin

• color: white, FDA grade

• adhesive: backing adhesive or not

• surface: smooth

• cross section: rectangle, round

• tensile strength: 8Mpa

• hardness: 30-70shore A

• density: 0.7-1.0g/cm3

• creep relaxation: 70%

• volatility: 1.0%

• PH: 0-14

• working pressure: 1.6Mpa in gas, 6.4Mpa in liquid

• working temperature: -168°C ~ +280°C(maximum +315°C)

• thickness: 1.5-7.0mm

• material: 60%PTFE + 40%bronze or phenolic + fabric

• pressure 1 5 M p a @ 2 5 ° C , 12Mpa@80°C, 8Mpa@120°C

• temperature: -60°C – +260°C

• speed: 15m/s

• high wearing resistance: normally 10times of cast iron guide, good accuracy maintenance

• low friction: friction coeffi- cient<0.04, only 1/3 of cast iron guide, reducing the driving-energy consumption

• no creeping: moving steadily

• material: PTFE fiber, aramid fiber, graphite, lubricant

• working press: 2-20Mpa

• working speed: 2-20m/s

• working temperature: -240°C ~ +288°C

• high density: 1.4g/cm3

• PH range: 0-14

• size: 3-50mm x 3-50mm x 5, 10, 15kgs

• terial: PTFE fiber, aramid fiber, graphite, lubricant

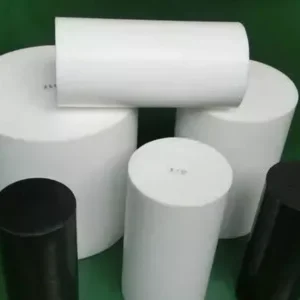

• material: PTFE, SS304 etc.

• filling: graphite, carbon, bronze

• quality: premium grade

• color: white, black

• surface: smooth

• tensile strength: 20-30Mpa

• hardness: 55+/-5shore D

• elongation at break: 200%

• density: 2.1-2.7g/cm3

• break down voltage: 10KV/ mm

• temp resist: -180°C – +260°C

• material: virgin PTFE

• quality: premium grade

• color: white, black, brown

• surface: smooth

• tensile strength: 20-30Mpa

• hardness: 55+/-5shore D

• elongation at break: 200%

• density: 2.1-2.3g/cm3

• break down voltage: 10KV/ mm

• temp resist: -180°C – +260°C

• material: pure PTFE expand

• tensile strength: ≥8Mpa

• elongation: ≥25%

• working pressure: 150-250kg/cm2

• density: 0.15-0.35g/cm3

• heat-resistance: +260°C

• cold-resistance: -180°C

• width: 3-100mm

• length: 5-50m

• thickness: 0.075-0.2mm

• material: 100% virgin silicone material

• quality: industrial grade, food grade

• color: translucent, dark red, black, milk white, blue, grey etc.

• surface: smooth

• tensile strength: 7.5-9.8Mpa

• hardness: 30, 40, 50, 60, 70, 80+/-5shore A

• elongation: 350-720%

• density: 1.25g/cm3

• tear strength: 26-42N/mm

• working temperature: -60°C – +250°C

• cell: closed cell

• material: virgin silicone sponge

• color: dark red, white, grey, black, beige, brown, blue etc.

• surface: double impression fabric

• tensile strength: 100-200PSI

• hardness: 10, 15, 20, 25, 30, 35, 40+/-5shore A (currently 20-25shore A)

• elongation: 100%

• density: 0.5-1.0g/cm3

• working temperature: -60°C – +220°C(moment 260°C)

• thickness: 1.5-50mm

• width: 0.1-1.5m(maximum 1.5m@more than 5mm thick- ness)

• length: 0.1-10m