Butterfly Valve – 25A

₮0.00Sizes

DN50 – DN300

Working pressures

Approved for pressures up to 16 bar

DN50 – DN300

Approved for pressures up to 16 bar

Dimensions, materials, design pressure and tightness adapted to customer´s requirements Actuators: Pneumatic, Electric, Hydraulic

From DN 80 up to DN 3000

Larger sizes on request.

Check with CMO Valves for the general dimensions of a specific damper butterfly.

From DN 80 up to DN 3000

Larger sizes on request.

Check with CMO Valves for the general dimensions of a specific damper butterfly.

The most significant difference between the ML and MF series is the differential working pressure (ΔP).

For lower pressures, choose the ML series (Light Butterfly);

For higher pressures, choose the MF series.

Maximum standard work pressure is 0.5 bar greater pressures upon request.

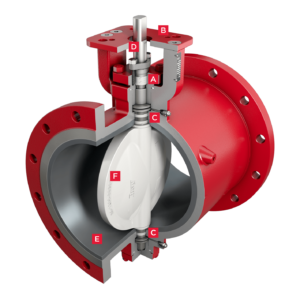

• Working Pressure :16 bar

• Working Temperatre :-10°C to 120°C for EPDM liner. -10°C to 82°C for NBR liner.

• Corrosion Protection :Internal- ly and externally liquid epoxy painted or fusion bonded ep- oxy powder coated (FBE).

• Working Pressure :16 bar

• Working Temperatre :-10°C to 120°C for EPDM liner. -10°C to 82°C for NBR liner.

• Corrosion Protection :Internal- ly and externally liquid epoxy painted or fusion bonded ep- oxy powder coated (FBE).

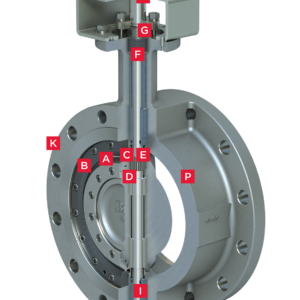

High-Performance Butterfly Valves are used in throttling ap- plications requiring large flow capacities and small installed footprints. They use a rotating eccentric disk to control flow through a pipe. The disk is generally operable through 90 de- grees and provides a linear flow characteristic. These valves have nominal sizes from DN50 to DN1800 (from NPS 2 to 72) and pressure class up to PN420 (CL2500 according to ASME) depending on the model.

• Replaceable, metal-reinforced seat, completely encapsulated by rubber, isolates

the stem and body from the media and eliminates seat distortion due to high vac-

uum or turbulence.

• Primary stem seal, formed by preloaded contact of disc hub with flatted seat sur- faces, completely isolates stem and body from the line media.

• Secondary stem seal, formed by an engineered interference fit of the stem through the seat, provides additional sealing integrity.

• Rounded, polished disc edge provides full 360 degree concentric seating, minimum flow restriction, lower seating and unseating torques and maximum seat life.

• Uninterrupted gasket surfaces help eliminate problems associated with seat retaining screws in the gasket surface and allows use of standard spiral wound gaskets.

• Valve stem designed to API 609 standards is blow-out resistant.

• Seat retaining ring is housed within the flange gasket ID to eliminate potential emission path.

• Face-to-face conforms to MSS SP-68 and can be configured to ISO 5752 short.

• Adjustable packing utilizes unique rocker-shaped gland bridge that compensates for uneven adjustment of gland nuts.

• Extended neck allows for two inches of clearance for insulation.

• Positive sealing which is mechanically achieved and does not rely on line pressure assistance.

• Bi-directional shut-off performance.

• Body design options: wafer, lugged or double flanged.

• Suitable for use on end-of-line service (lugged and double flanged).

• Available in 3 design options. Soft seated, fire-safe or metal seated.

Flange x Weldable Pipe End

100% Pressure Tested Using Computer Controlled Mass Flow

Zero Leakage Design

Includes Face O-Ring

Includes Valve Cover Plate & Mounting Hardware

Flange x Weldable Pipe End

100% Pressure Tested Using Computer Controlled Mass Flow

Zero Leakage Design

Does Not Include Face O-Ring

Flange x Weldable Pipe End

100% Pressure Tested Using Computer Controlled Mass Flow

Zero Leakage Design

Does Not Include Face O-Ring

Stainless Steel Locking Bolt & Nut for Hand Lever

Flange x Weldable Pipe End

100% Pressure Tested Using Computer Controlled Mass Flow

Zero Leakage Design

Includes Face O-Ring

Flange x Weldable Pipe End

100% Pressure Tested Using Computer Controlled Mass Flow

Zero Leakage Design

Includes Face O-Ring

Stainless Steel Bolt & Nut for Securing Hand Lever

• Size Range:2” – 20” (50mm – 500mm)

• Body Style:Wafer & Flanged Long Body

• Temperature Range:-20°F to 300°F (-29°C to 150°C)

• Pressure Ratings:230 psi (16 Bar)

• Body Materials:Ductile Iron, Stainless Steel

• Disc Materials:Chrome-Molly Iron (Hardened), PSZ Ceramic (Partially Stabilized Zirconia)

• Stem Materials:Stainless Steel